In power plants and industrial applications, generators are the lifeblood of continuous electricity production. But like any complex machine, generators are susceptible to wear and degradation—particularly in one of their most vital components: the stator.

Over time, the stator coils lose their effectiveness due to thermal stress, electrical faults, and environmental exposure. To avoid energy losses, unplanned downtime, or costly replacements, regular stator rewinding becomes essential. In this article, we explore how stator rewinding enhances generator performance and prolongs its lifespan.

⚙️ What is Generator Stator Rewinding?

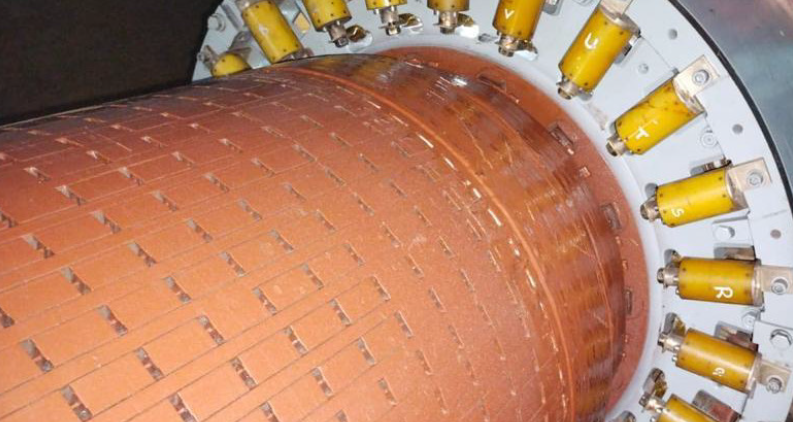

Stator rewinding is the process of replacing the worn, shorted, or damaged coils within the stator core of a generator. The stator is responsible for generating the magnetic field that interacts with the rotor to produce electricity. When these coils deteriorate, efficiency drops, and operational risk increases.

By rewinding the stator, the generator regains optimal magnetic and electrical properties—restoring performance, improving safety, and maximizing output.

✅ Benefits of Regular Stator Rewinding

⚡ 1. Enhanced Efficiency

Old or damaged windings cause increased electrical resistance, which results in energy loss. Rewinding with modern insulation and precision techniques significantly improves the generator’s electrical efficiency.

💸 2. Cost-Effective Maintenance

Rewinding is a fraction of the cost of purchasing a new generator. It extends the equipment’s life without sacrificing performance, helping plants avoid unplanned capital expenditure.

🛠️ 3. Prolonged Generator Life

Routine rewinding prevents catastrophic failures and protects the integrity of the generator. With proper care, generators can operate reliably for decades.

🔄 4. Improved Reliability & Uptime

A properly rewound stator ensures consistent performance and reduces the risk of unexpected breakdowns. This means fewer shutdowns and more stable power generation.

🧩 Steps in the Stator Rewinding Process

- Generator Disassembly – The unit is safely dismantled to access the stator windings.

- Coil Removal – Damaged or aged coils are carefully extracted from the stator core.

- New Coil Installation – Custom-made coils, insulated with advanced materials, are installed to restore optimal conductivity.

- Reassembly & Testing – The generator is reassembled and tested for insulation resistance, phase balance, and vibration.

Each step requires skilled craftsmanship, strict tolerances, and adherence to safety and quality standards.

🔧 Why Choose MACROMECH POWER for Stator Rewinding?

At MACROMECH POWER, we specialize in comprehensive generator servicing, including precision stator rewinding. Our technicians use advanced testing and winding techniques to ensure your generator performs better, lasts longer, and consumes less energy.

Our facility is equipped to handle all generator sizes, from small industrial units to large utility-scale machines. We also provide on-site inspection, rotor balancing, and thermal analysis to support full generator health diagnostics.

🔋 Conclusion

Stator rewinding is more than a repair—it’s an investment in your power plant’s efficiency and longevity. By integrating regular rewinding into your maintenance schedule, you reduce long-term costs, minimize operational risks, and secure continuous power delivery.

Don’t wait for performance to drop—optimize your generator before failure happens. Trust the experts at MACROMECH POWER to keep your energy systems running at full potential.