Power plant turbines are among the most critical and high-value assets in any generation facility. Over time, even the most robust turbines begin to show signs of wear and reduced efficiency due to continuous high-speed operation, heat exposure, and environmental factors. Rather than investing in complete replacements, many plant operators are now turning to turbine refurbishment as a smart, cost-effective alternative.

In this blog, we explore the key benefits of turbine refurbishment and why it’s a reliable, performance-driven choice for power plant operators.

✅ Top Benefits of Turbine Refurbishment

💰 1. Cost Savings

Refurbishing a turbine can reduce capital expenses by up to 50% compared to purchasing new equipment. It offers the same performance uplift without the hefty price tag of new installations.

⚡ 2. Improved Performance

Through rebalancing, blade repair, and part replacements, refurbished turbines often return to — or even exceed — original efficiency levels. This results in increased power output and reduced energy loss.

🛠️ 3. Extended Equipment Lifespan

Turbine refurbishment rejuvenates worn components, restoring integrity and reliability. With proper servicing, a refurbished turbine can continue to operate efficiently for several more years.

🌱 4. Environmental Sustainability

By reusing key turbine parts, refurbishment minimizes waste and reduces the carbon footprint associated with manufacturing and logistics of new turbines.

🔍 Common Issues Solved by Turbine Refurbishment

Refurbishment isn’t just about saving costs—it actively solves technical challenges. Some of the common turbine issues that can be resolved include:

- Blade Wear & Tear: Continuous rotation and high-temperature exposure gradually erode turbine blades, reducing efficiency.

- Rotor Imbalance: Causes vibrations, which can lead to further internal damage if not corrected.

- Erosion & Corrosion: Steam and gas flows cause pitting and material loss over time, affecting flow dynamics and performance.

👷♂️ Why Work with Experts?

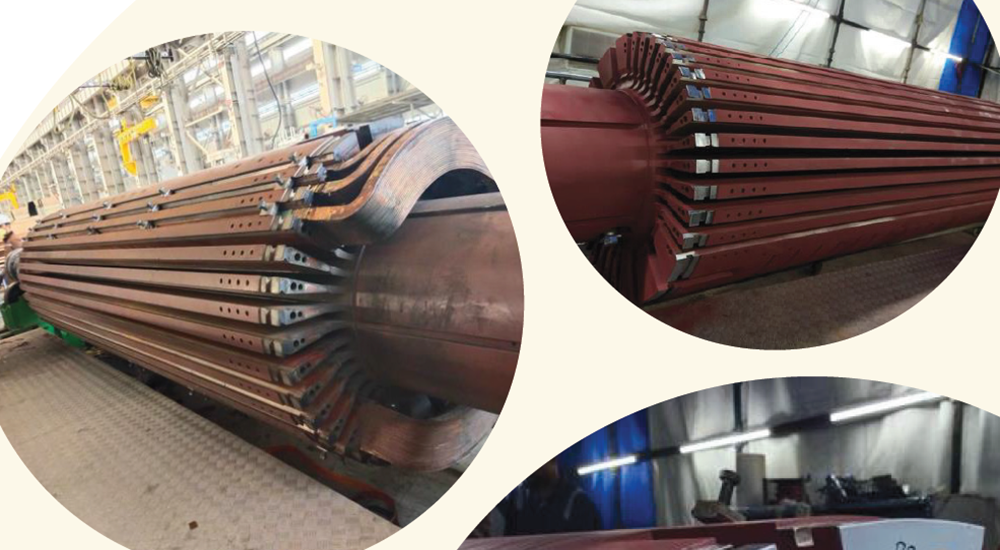

Turbine refurbishment is a precise, technical process. It involves disassembly, inspection, defect detection, part fabrication, and reassembly—often under strict tolerances. Working with an experienced engineering team ensures:

- Compliance with OEM standards

- Use of high-quality materials and tools

- Long-term reliability and plant safety

- Minimal downtime during execution

💼 Refurbishment with MACROMECH POWER

At MACROMECH POWER, we provide industry-leading turbine refurbishment solutions that restore performance, extend life, and reduce operational costs. Our engineers follow a structured approach—from initial diagnostics to final testing—to ensure your equipment performs at its best. Whether it’s steam, gas, or hydro turbines, we tailor our refurbishment process to suit your plant’s specific needs.

📝 Conclusion

Turbine refurbishment is more than a maintenance procedure—it’s a strategic decision that optimizes performance, controls costs, and supports sustainability. If you’re looking to enhance turbine efficiency without the burden of new equipment investment, refurbishment is the answer.

Trust experience. Trust performance. Trust MACROMECH POWER.